Combustible Dust

On this page

- What is a combustible dust?

- What is the technical definition for combustible dust?

- What are examples of materials that can be a combustible dust hazard?

- What workplaces are at risk for a dust explosion?

- How are combustible dusts hazardous?

- How do combustible dust explosions happen?

- What is deflagration?

- What are primary and secondary dust explosions?

- What conditions are needed for a dust explosion to happen?

- How do employers identify a combustible dust hazard?

- What are prevention measures?

- What can workers do to protect themselves?

What is a combustible dust?

Back to topA combustible dust is any material (finely divided solid particles) that has the ability disperse in air and catch fire and explode when exposed to an ignition source. Combustible dust may include materials that are in the physical states of powders, flakes, fines, fibers, etc.

Combustible dusts can include:

- most solid organic materials (such as sugar, flour, grain, wood, etc.)

- carbonaceous materials (e.g., charcoal, soot)

- textile fibres (e.g., cotton)

- many metals, and

- some nonmetallic inorganic materials.

Some of these materials are not "normally" combustible, but they can burn or explode if the particles are the right size and in the right concentration.

Therefore any activity that creates dust should be investigated to see if there is a risk of that dust being combustible. Dust can collect on surfaces such as rafters, roofs, suspended ceilings, ducts, crevices, dust collectors, and other equipment. When the dust is disturbed and under certain circumstances, there is the potential for a serious explosion to occur. The build-up of even a very small amount of dust can cause serious damage.

What is the technical definition for combustible dust?

Back to topThe technical definitions for combustible dust vary. For example, the Hazardous Products Regulation (for Workplace Hazardous Materials Information System (WHMIS) 2015) defines combustible dust as " a mixture or substance that is in the form of finely divided solid particles that, upon ignition, is liable to catch fire or explode when dispersed in air".

Another example is Alberta's Occupational Health and Safety Code which defines combustible dust as "a dust that can create an explosive atmosphere when it is suspended in air in ignitable concentrations".

The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as "a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations".

The National Fire Protection Agency (NFPA) defines combustible dust as “a finely divided combustible particulate solid that presents a flash-fire hazard or explosion hazard when suspended in air or the process-specific oxidizing medium over a range of concentrations” in Standard 652-2019, The Fundamentals of Combustible Dust.

What are examples of materials that can be a combustible dust hazard?

Back to topMany materials can become combustible under specific situations. Workplaces may either purchase such materials for use, or generate dusts as part of their processes. Examples of materials include:

- agricultural products such as egg whites, powdered milk, cornstarch, sugar, flour, grain, potato, rice, etc.

- metals such as aluminum, bronze, magnesium, zinc, etc.

- chemical dusts such as coal, sulphur, etc.

- pharmaceuticals

- pesticides

- rubber

- wood

- textiles

- plastics

There are many, many more types of materials that may become a combustible dust. The US OSHA has created a poster which lists more examples.

What workplaces are at risk for a dust explosion?

Back to topDust explosions have occurred in many different types of workplaces and industries, including:

- Agriculture (e.g., fertilizer plants, composting facilities, grain elevators, silos, etc.)

- Food production (e.g., sugar factories, bakeries)

- Chemical manufacturing (e.g., rubber, plastics, pharmaceuticals),

- Fabric products manufacturing,

- Woodworking facilities,

- Metal processing and manufacturing (e.g., zinc, magnesium, aluminum, iron),

- Recycling facilities (e.g., paper, plastics, metals), and

- Coal mining, processing or coal-fired power plants

Dusts are created when materials are transported, handled, processed, polished, ground and shaped. Dusts are also created by abrasive blasting, cutting, crushing, mixing, sifting or screening dry materials. The buildup of dried residue from the processing of wet materials can also generate dusts. Essentially, any workplace that generates dust is potentially at risk.

How are combustible dusts hazardous?

Back to topThe primary hazard is that combustible dusts can catch fire, create a flash fire, or cause an explosion.

The specific product or material may also cause health effects, such as lung disease or cancer, which is not addressed in this document. Please see other OSH Answers on that specific product, or contact CCOHS’s Safety Infoline (Inquiries Service) for more information.

How do combustible dust explosions happen?

Back to topAny fire needs three elements. These elements are known as the "fire triangle":

1. Fuel to burn2. Oxygen

3. Ignition source (heat, spark, etc. )

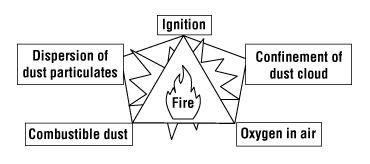

A dust explosion needs two additional elements - known as the "dust pentagon":

4. Dispersion of dust particles in the right concentration, and

5. Confinement of the dust cloud.

Dispersion means the dust particles are suspended in air. (Note that flash fires may occur without the 5th element of confinement). Confinement means the dust is in an enclosed or limited space. This restriction allows pressure to build up, increasing the likelihood of an explosion.

Figure 1

Figure 1 shows the dust explosion pentagon. Figure from Occupational Safety and Health Administration (OSHA).

What is deflagration?

Back to topDeflagration is a term often used to describe combustible dust explosions. A deflagration is an "ordinary" fire such as a gas stove, burning wood or paper, and even the burning of gasoline vapour inside the cylinder of an automobile. In a deflagration, a burning substance releases heat, hot gases, and energetic particles or sparks that ignite and spread the fire.

In a dust explosion, the deflagration processes happens so rapidly that the heated air and gaseous fire products (such as carbon dioxide) produce extreme air pressure that can blow out walls and destroy structures.

What are primary and secondary dust explosions?

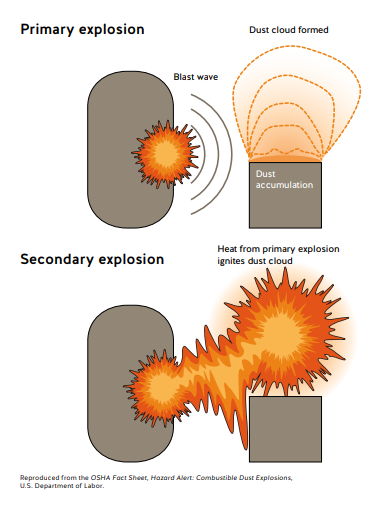

Back to topWhen combustible dusts ignite, there are often two explosions known as primary and secondary explosions.

The primary dust explosion is the first explosion. It occurs when there is a dust suspension in a confined space (such as a container, room, or piece of equipment) that is ignited and explodes.

The primary explosion will shake other dust that has accumulated. When this dust becomes airborne, it also ignites. This secondary dust explosion is often more destructive than the primary one.

Figure 2

Figure 2 shows primary and secondary dust explosions. Figure from Occupational Safety and Health Administration (OSHA) and WorksafeBC.

What conditions are needed for a dust explosion to happen?

Back to topThe basic requirements for a dust explosion to occur are that combustible dusts are suspended in air and are ignited. In practice, for a dust explosion to occur, a number of conditions must be met including:

- The dust must be combustible and release enough heat when it burns to sustain the fire.

- The dust must be capable of being suspended in air.

- The dust must have a particle size capable of spreading the flame.

- The concentration of the dust suspension must be within the explosible range.

- An ignition source must be in contact with the dust suspension.

- The atmosphere must contain sufficient oxygen to support and sustain combustion.

- There is a form of confinement or enclosure that allows pressure to build.

How do employers identify a combustible dust hazard?

Back to topThere are many variables that must be considered - the particle size of the dust, the method of dispersion, ventilation system characteristics, air currents, ignition sources, confinement of the dust cloud, physical barriers, and so on. As a result, the often quoted "rule of thumb" about dust accumulation (such as being able to write in the dust, or the dust being the thickness of a paperclip, dime or quarter, or the amount of visibility through a dust cloud) is not always reliable.

In order to determine the level of risk from combustible dust, a risk assessment should be completed by a competent person (e.g., safety engineer, industrial/occupational hygienist, etc.). A risk assessment is a process that determines:

- if the dust is combustible

- the sources of combustible dust (e.g., the materials and processes used in the manufacturing methods)

- the areas where combustible dust accumulates (e.g., visible or hidden – equipment, beams, pipes, etc.)

- are there processes that cause dust to enter the air or create dust clouds

- if there are processes to prevent the dust from accumulating

- the likelihood (probability and degree) the dust will be a flash fire or explosion hazard

- the presence of ignition sources (e.g., hot surfaces, flames, friction points, sparks, electrostatic discharges, etc.)

- the likelihood there will be an illness, injury or death in a hazardous situation resulting from a combustible dust flash fire or explosion

Best practice is to keep the workplace as dust free as possible.

Below are some questions that may help.

Processes

- Do you manufacture or use any materials (and their by-products) that can become a dust?

- Do you have processes such as abrasive blasting, cutting, grinding, sieving, polishing, cleaning, or other tasks that create dust?

Research/Information

- Have you researched if the dust present is combustible?

- Are there documented cases reported in literature about the materials in your workplace being associated with a combustible dust explosion?

Note: It is very important to research the materials and products used in your workplace. Stating the possibility of a combustible dust hazard is now a requirement on the Safety Data Sheet (SDS) under WHMIS 2015. Older Material Safety Data Sheets (MSDSs) may not provide the same information so additional research may be necessary. Other sources of information include to check if the material is classified as a combustible dust include referring to:

- Transport of Dangerous Goods (TDG) Class 4 Flammable solids or liable to spontaneous combustion

- documents such as National Fire Protection Association (NFPA) standards such as the NFPA 652 - Standard on the Fundamentals of Combustible Dust or other NFPA standards on combustible dusts that are industry or commodity specific (e.g., coal, sulfur, metals),

- the USA OSHA Combustible Dust poster and related information,

- chemical textbooks, and

- other reliable sources.

Ignition sources

- Do you have ignition sources (e.g. , sparks, fire, flames, stoves, heat sources, kilns, or welding flames)?

- Can dust enter or accumulate on electrical enclosures or equipment?

- Does your workplace have a no-smoking policy? Are there measures to isolate smoking and ignition sources away from production areas?

Housekeeping

- Do you know if there are open areas and overhead structures where dusts may accumulate?

- Have you looked for "hidden" areas where dust may accumulate (e.g. , behind false ceilings, inside ventilation or conveyor equipment, in ducts, on support beams, etc. )?

- Do you have a housekeeping program to regularly remove dust?

- Do you have a dust collection system in place?

- If yes, does your dust collection system conform to combustible dust removal standards and local requirements (e.g. , fire code)?

Education and training

- Are employees aware of combustible dust and its hazards?

- Do employees follow housekeeping rules and take steps to reduce dust and remove ignition sources?

- Have employees been trained and educated on safe methods for cleaning?

What are prevention measures?

Back to topOnce the hazards are identified, appropriate control measure can be put in place

Eliminate

- Use alternative products where possible that are not combustible or are less hazardous.

- Change manufacturing processes to eliminate (or reduce) the amount of dust created. (e.g., wet cutting methods, liquid ingredients, etc.)

- Design work surfaces to minimize the accumulation of dust (such as horizontal surfaces like window ledges, beams, light fittings, etc. ).

- Eliminate "hidden" areas where dust can accumulate unnoticed.

- Do not create dust when cleaning such as by using brooms or compressed air hoses to clean surfaces. Only use wet methods or vacuums approved for dust collection

Substitute

Install smooth ceilings and other surfaces (instead of a rough finish) to minimize dust accumulation and to make cleaning easier.

Engineering

- Only use a dust collection or dust extraction system that is designed to eliminate or control combustible dust. Most types of fans typically stirs the dust, adding dust particles into the air and worsening the situation.

- Use an appropriate dust extraction and collection system with the inlet located as close to the dust producing process as possible. Follow required standards and codes when installing these systems. Locate dust collectors outdoors, where possible.

- Set up the dust producing process so it can only run with the ventilation operating properly.

- Direct explosion venting away from areas where there may be employees.

- Use appropriate electrical and ventilation equipment.

- Keep all mechanical and electrical equipment in good repair.

- Keep static electricity under control, which includes the bonding and grounding of equipment. Check all bonded and grounded equipment regularly to ensure the bonds are in good condition.

- Control ignition sources, such as bond and ground conductive equipment.

- Check equipment that may wear (e.g. , bearings) as they may generate heat and become an ignition source.

- Remove open flames, sparks, friction, heat sources, and other sources of ignition.

- Select and use intrinsically safe tools or machinery.

- Put covers around pipes and cables, or embed pipes and cables in the walls, where possible, to reduce surfaces where dust can accumulate.

Administration

- Develop and implement a combustible dust inspection and control program which outlines how often inspections will occur and how dust will be controlled. Include inspection of machines, ducts, and ventilation systems for dust.

- Develop a hot work permit system for activities such as welding and cutting.

- Develop an ignition control program to eliminate or reduce sources of ignition. Keep ignition sources away from dusty areas or use suitable controls.

- Develop safe practice for the storage of combustible dust.

- Confirm fire and explosion protection and prevention equipment is installed and used according to applicable standards or legislation.

- Establish a fire safety plan.

- Inspect for dust at regular intervals.

- Establish a housekeeping program that will remove dust appropriately and regularly.

- Use proper equipment and techniques when cleaning dust. Care must be taken to minimize dust clouds, and only use vacuums approved for dust collection.

- Regularly inspect machines, ducts, and ventilation systems for dust. Repair or clean promptly.

- Educate all employees about combustible dusts, the hazards, and how they can help eliminate the risk of fire and explosions.

What can workers do to protect themselves?

Back to topWorkers must:

- Follow the training provided by their employer on how to identify combustible dust materials, how to safely handle combustible dust, and how to follow emergency procedures.

- Be familiar with the material’s hazards and the work area hazards before you start your work activities.

- Never bring ignition sources into an area where combustible dust is being processed or handled.

- Wear any required personal protective equipment (PPE).

- Immediately report unsafe conditions that can lead to ignition of the combustible dust such as:

- Immediately report spills of combustible dust to their supervisor

- Immediately report any process issues or equipment failure

- Presence of sparks in the combustible dust area

- Fact sheet last revised: 2022-02-28