Hazard and Risk - Hierarchy of Controls

On this page

- What is the hierarchy of controls?

- What is meant by elimination?

- What is substitution?

- What are examples of engineering control methods?

- What are examples of administrative controls?

- What should I know about personal protective equipment (PPE) as a hazard control method?

- Can more than one control method be used or followed?

- Should the adequacy of controls be reviewed or evaluated?

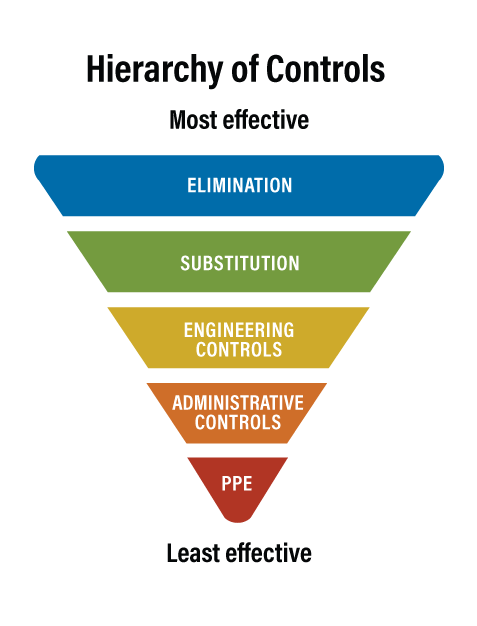

What is the hierarchy of controls?

Back to topThe hierarchy of controls is a step-by-step approach to eliminating or reducing workplace hazards. It ranks controls from the most effective level of protection to the least effective level of protection. When choosing a control method, start from the top of the inverted pyramid. Assess the feasibility of the first layer of controls (elimination) before moving on to the second layer (substitution). Continue this process until you reach the bottom of the pyramid and have identified as many controls as needed to adequately protect the worker from the hazard.

The hierarchy of controls is shown in the graphic below.

Figure 1: Hierarchy of Control

Some sources may use a variation of this hierarchy of controls. For example, the CSA Standard 1002-12 (R2022): Occupational health and safety – Hazard identification and elimination and risk assessment and control includes a layer called "systems that increase awareness of potential hazards". For example, visual or audible alarms or warning signs. This systems layer is placed in between engineering controls and administrative controls.

Regardless of the number of layers included, the hierarchy should be considered in the order presented (it is always best to try to eliminate the hazard first, etc.).

What is meant by elimination?

Back to topElimination is the process of removing the hazard from the workplace. It is the most effective way to control a risk because the hazard is no longer present. It is the preferred way to control a hazard and should be used whenever possible.

Examples of elimination control methods include:

- Purchasing equipment that is not noisy

- Using a reach pole, where feasible, for window washing to eliminate working from heights

- Removing and properly disposing of products that are stored in the workplace and are no longer being used

- Avoiding driving during extreme winter weather conditions

What is substitution?

Back to topIf eliminating a hazard is not possible, substitution is the next control method that should be considered.

Substitution is the act of replacing something with another thing… in this case, a hazard is replaced with a less hazardous one. The hazards and risks associated with an alternative must be thoroughly assessed to determine if it is an appropriate replacement. Care must be taken to make sure that the new hazard is actually lower, and that one hazard is not being replaced with another that is just as harmful or more harmful.

Examples of substitution controls include:

- Replacing solvent-based paints with a water-based alternative

- Using a larger granule form of a product instead of a fine powder to reduce dust generation

- Using electric motors rather than diesel ones to eliminate diesel exhaust emissions

Substitution is often used when workers are exposed to hazardous products. Table 1 below provides some examples:

Table 1: Sample Chemical Substitutions

| Instead Of: | Consider: |

| carbon tetrachloride (causes liver damage, cancer) | 1,1,1-trichloroethane, dichloromethane |

| benzene (causes cancer) | toluene, cyclohexane, ketones |

| pesticides (causes various effects on body) | "natural" pesticides such as pyrethrins |

| organic solvents (causes various effects on body) | water-detergent solutions |

| leaded glazes, paints, pigments (causes various effects on body) | versions that do not contain lead |

| sandstone grinding wheels (causes severe respiratory illness due to silica) | synthetic grinding wheels such as aluminum oxide |

Remember, however, that you need to make sure the substitute product will not cause any harmful effects, and to control and monitor exposures to make sure that the replacement product is below occupational exposure limits.

Another type of substitution includes using the same chemical but to use it in a different form. For example, a dry, dusty powder may be a significant inhalation hazard but if this material can be purchased and used as pellets or crystals, there may be less dust in the air and therefore less exposure.

Figure 2

See the OSH Answers document Substitution of Chemicals: Considerations for Selection for more information.

What are examples of engineering control methods?

Back to topEngineering controls are methods that will control the hazard at the source, before it comes in contact with the worker.

Engineering controls can be built into the design of a plant, equipment, or process to minimize the hazard. Engineering controls are a very reliable way to control worker exposures as long as the controls are designed, used, and maintained properly. Examples of engineering controls are:

- Isolation – separating workers from the hazard by distance or the use of barriers

- Enclosures – placing the material or process in a closed system (e.g., enclosed machines, booths, etc.)

- Guarding and shielding – using guards around moving parts of machinery

- Ventilation – using local exhaust or general dilution ventilation to remove or reduce airborne products

- Mechanical lifting devices– using mechanical methods to lift or move objects instead of manual lifting

- Guardrails – using guardrails to prevent a fall

More information on engineering controls includes the following:

Process Control

Process control involves changing the way a job activity or process is done to reduce the risk. Monitoring should be done before and as well as after the change is implemented to make sure the changes did, in fact, control the hazard.

Examples of process changes include to:

- Use wet methods rather than dry when drilling or grinding. "Wet method" means that water is sprayed over a dusty surface to keep dust levels down or material is mixed with water to prevent dust from being created.

- Use steam cleaning instead of solvent degreasing (but be sure to evaluate the potential high-temperature hazard being introduced, such as heat stress).

- Float "balls" on open-surface tanks that contain solvents (e.g., degreasing operations) to reduce solvent surface area and lower solvent loss.

- Instead of conventional spray painting, try to dip, paint with a brush, or use "airless" spray paint methods. These methods will reduce the amount of paint that is released into the air.

- Decrease the temperature of a process so that less vapour is released.

- Use automation - the less workers have to handle or use the materials, the less potential there is for exposure.

- Use mechanical transportation rather than manual methods.

Enclosure and Isolation

These methods aim to keep the chemical "in" and the worker "out" (or vice versa).

An enclosure keeps a selected hazard "physically" away from the worker. Enclosed equipment, for example, is tightly sealed and it is typically only opened for cleaning or maintenance. Other examples include "glove boxes" (where a chemical is in a ventilated and enclosed space, and the employee works with the material by using gloves that are built-in), abrasive blasting cabinets, or remote control devices. Care must be taken when the enclosure is opened for maintenance as exposure could occur if adequate precautions are not taken. The enclosure itself must be well maintained to prevent leaks.

Isolation places the hazardous process "geographically" away from the majority of the workers. Common isolation techniques are to create a contaminant-free or noise-free booth either around the equipment or around the employee workstations.

Ventilation

Ventilation is a method of control that "adds" and "removes" air in the work environment. General or dilution ventilation can remove or dilute an air contaminant if designed properly. Local exhaust ventilation is designed to remove the contaminant at the source so it cannot disperse into the work space, and it generally uses lower exhaust rates than general ventilation (general ventilation usually exchanges the air in the entire room).

Local exhaust ventilation is an effective means of controlling hazardous exposures but should be used when other methods (such as elimination or substitution) are not possible.

Figure 3 Example of Local Exhaust Ventilation

The design of a ventilation system is very important and must match the particular process and product in use. Expert guidance should be sought. It is a very effective control measure but only if it is designed, tested, and maintained properly.

Because products are exhausted to the outdoors, you should also check with your local environment ministry or municipality for any environmental air regulations or bylaws that may apply in your area.

What are examples of administrative controls?

Back to topAdministrative controls involve developing procedures to ensure the work is conducted in a way that minimizes the hazard. Examples include developing or changing policies, implementing or improving training and education, and developing or enhancing work practices and procedures.

Administrative controls are ranked lower than elimination, substitution, and engineering controls because these methods do not necessarily remove or reduce the hazard from the workplace. For example, administrative controls limit workers' exposures by scheduling shorter work times in contaminant areas or by implementing other "rules". These control measures have many limitations because the hazard itself is not actually removed or reduced. Administrative controls should be used in combination with other control measures where possible.

Methods of administrative control include:

- Using job-rotation schedules or a work-rest schedule that limits the amount of time an individual worker is exposed to a substance.

- Implementing a preventative maintenance program to keep equipment in proper working order

- Scheduling maintenance and other high-exposure operations for times when few workers are present (such as evenings and weekends).

- Restricting access to a work area.

- Restricting the task to only those competent or qualified to perform the work.

- Using signs to warn workers of a hazard.

More information about types of administrative controls is provided below:

Work Practices

Elements of safe work practices include:

- Developing and implementing safe work procedures or standard operating procedures.

- Training and education of employees about the operating procedures as well as other necessary workplace training (including WHMIS).

- Establishing and maintaining good housekeeping programs.

- Keeping equipment well maintained.

- Preparing and training for emergency response for incidents such as spills, fire, or employee injury.

Education and Training

Employee education and training on how to conduct their work safely is a critical element of any complete workplace health and safety program. Training must cover not only how to do the job safely but it must also ensure that workers understand the hazards and risks of their job, and the controls in place to protect them. It must also provide them with information on how to protect themselves and co-workers.

Good Housekeeping

Good housekeeping is essential to prevent the accumulation of hazardous or toxic materials (e.g., build-up of dust or contaminant on ledges, or beams), or hazardous conditions (e.g., poor stockpiling).

For more information about workplace housekeeping, please see the OSH Answers document Workplace Housekeeping - Basic Guide.

For more information about combustible dust, please see the OSH Answers document Combustible Dusts.

Figure 4

Emergency Preparedness

Being prepared for emergencies means making sure that the necessary equipment and supplies are readily available and that employees know what to do when something unplanned happens such as a release, spill, fire, or injury. These procedures should be written and employees should have the opportunity to practice their emergency response skills regularly.

Please see the OSH Answers document on emergency planning for more information.

Personal Hygiene Practices and Facilities

Personal hygiene practices are another effective way to reduce the amount of a hazardous material absorbed, ingested, or inhaled by a worker.

Examples of personal hygiene practices include:

- Washing hands after handling material and before eating, drinking or smoking.

- Avoiding touching lips, nose, and eyes with contaminated hands.

- No smoking, drinking, chewing gum or eating in the work areas - these activities should be permitted only in a "clean" area.

- Not storing hazardous products in the same refrigerator as food items.

Please see the OSH Answers documents on Workplace Housekeeping, Hand Washing: Reducing the Risk of Common Infections and Good Hygiene Practices - Reducing the Spread of Infections and Viruses for more information.

What should I know about personal protective equipment (PPE) as a hazard control method?

Back to topPersonal protective equipment (PPE) refers to anything workers wear to help protect them from workplace hazards.

The use of PPE as the main method to control exposures should be limited to situations where elimination, substitution, engineering, or administrative controls are not practicable, or when:

- Additional protection is required because other control methods are not sufficient to reduce the hazard

- The hazard is a result of a temporary or emergency condition

PPE limits exposure to the harmful effects of a hazard but only if the PPE is worn and used correctly. Examples of PPE include:

- Respiratory protection

- Skin protection (e.g., coveralls, aprons, full body suits)

- Gloves

- Eye protection (e.g., face shield, goggles)

- Foot protection

- Hearing protective devices (e.g., ear plugs, ear muffs)

The choice of what type of PPE is required must be based on the specific hazard found at the workplace.

No matter which type of PPE is used, it is essential to have a complete PPE program in place. For more information about PPE programs, please see the following document Designing an Effective PPE Program.

Can more than one control method be used or followed?

Back to topYes. Sometimes a hazard cannot be controlled using a single type of control method. If a hazard cannot be eliminated, a combination of controls may be required.

For example:

- Using a scissor lift instead of a ladder (substitution). Workers should be trained on the safe use of the equipment and follow safe work procedures (administrative controls). When working at heights, workers should also use PPE, including a full body harness and lanyard attached to an anchor point, there is a risk of injury from falling.

- Driving in the winter for work. Controls may include not driving during extreme winter weather (elimination), determining if there are any other options for driving, such as public transit (substation), use of winter tires (engineering), and driver training (administrative).

Should the adequacy of controls be reviewed or evaluated?

Back to topYes. It is important to determine the effectiveness of the control methods implemented and adjust as required.

Controls must not create new hazards. For example, if wearing PPE contributes to other hazards (e.g., heat stress), then it is important to review if other control methods are possible or if additional precautions are needed.

Monitor both the hazard and the control method to make sure that the control is working effectively and that exposure to the hazard is reduced or eliminated. Consider the following questions:

- Have the controls effectively eliminated or reduced worker exposure?

- Have any new hazards been created?

- Are new hazards appropriately controlled?

- Are any other methods required?

- Are workers trained on the control methods?

- What else can be done to eliminate or reduce exposure?

- If there is a change at the workplace, does this impact the hazard or the control methods?

- Fact sheet first published: 2022-06-03

- Fact sheet last revised: 2024-08-14