Noise - Control Measures

On this page

- How is noise made?

- What are the steps to take to control the noise in the workplace?

- How can we reduce the noise exposure?

- What engineering controls can be used to reduce vibration-induced noise?

- What engineering controls can be used to reduce aerodynamic-induced noise?

- What are other engineering controls?

- What other general measures can I take to control the noise?

How is noise made?

Back to topSound can be produced by vibration or as a result of aerodynamic systems.

Vibration-induced noises are produced by:

- Mechanical shocks and friction between parts (e.g., hammering, pressing, running gears, bearings, cutting tools, chutes, hoppers, etc.)

- Out-of-balance moving parts (e.g., unbalanced rigid rotors)

- Vibration of large structures (e.g., ventilation ducts, guards on machines, equipment supporting structures, etc.)

The sound may be amplified by reflective surfaces that are around the devices.

Aerodynamic sources of noise are air or fluid flows through pipes and fans or as the pressure drops in the air distribution system. Examples include:

- Steam released through exhaust valves

- Aircraft jets

- Turbulent flow of water through pipes

- Fans

- Combustion motors

For basic information on sound generation, please see the OSH Answers fact sheet: Noise – Basic Information.

What are the steps to take to control the noise in the workplace?

Back to topThe steps that must be taken in order to effectively and efficiently control the noise in the workplace are:

- Identify the sound sources: vibrating sources and aerodynamic flow.

- Identify the path of the noise from the source to the worker.

- Determine the sound level of each source.

- Determine the relative contribution to the excessive noise of each source and rank the source accordingly. To obtain significant noise attenuation, the dominant source should be controlled first.

- Know the acceptable exposure limits identified in the health and safety legislation and quantify the necessary sound reduction.

- Identify controls by taking into consideration the degree of sound attenuation, operation, and productivity restraints and cost.

- Create a hearing conservation program that includes noise measurement, assessment, and control. For more information, see Noise - Hearing Conservation Program.

How can we reduce the noise exposure?

Back to topThe exposure to noise can be reduced by eliminating the source of noise (if possible), substituting the source with a quieter one, applying engineering modifications, using administrative controls, and by using protective equipment.

The best way to reduce exposure to noise is to eliminate it at the design stage. In terms of equipment, always try to choose features that will reduce the noise level to a minimum acceptable level. In terms of new installations, select quiet equipment, have a procurement policy that opts for acquiring quiet equipment, and eliminate design flaws which would amplify the noise.

Engineering modifications include changes that affect the source or the path of the sound. Engineering controls are the preferred method of noise control in already established workplaces where noise protection was not factored in at the design stage. It is generally agreed that controlling the source is more cost-effective than those controlling noise along the path. See the engineering controls section below for examples.

Administrative controls are measures that control the noise at the worker. These controls should be used in addition to engineering controls, and they may include:

- Scheduling noisy processes during off-peak hours when fewer workers are present

- Implementing a hearing conservation program

- Providing job rotation to reduce the length of time a worker is required to work in a noisy area

- Developing safe work practices

- Training

- Regular audiometric testing

- Monitoring workplace exposure

- Implementing a preventive maintenance program and frequent inspections of noise-generating or vibrating equipment

Depending on the type and level of noise, the number of workers exposed, and the type of work, engineering controls might not always be possible. A combination of administrative control (e.g., limiting exposure length) and personal protection equipment such as ear muffs or ear plugs may be considered. However, we must keep in mind that the administrative measures and the use of PPE may not be effective in protecting the workers (e.g., PPE may be used incorrectly or may not be used at all; administrative controls may not be followed, etc.). The use of PPE should be the last resort for controlling the exposure to noise.

For information about hearing protectors, please refer to our Hearing Protectors OSH Answers fact sheet.

What engineering controls can be used to reduce vibration-induced noise?

Back to topSome of the engineering controls recommended for reducing vibration at the source are:

- Modifying the energy source such as reducing the speed of the fan, reducing the force of impact, etc.

- Damping or covering surfaces which vibrate due to mechanical forces (e.g., chutes and hoppers) with viscoelastic materials such as plastic, silicone, hard rubber and other elastomeric polymers. Single-layer damping occurs when the surface is covered with a layer of material which is one to three times thicker than the surface itself. This method is suitable for thin structures.

To prevent damage due to friction and impact with other materials, the damping material may be sandwiched between the wall of the equipment and a steel sheet or another material resistant to abrasion. This treatment is known as constraint layer treatment, and is adequate for chutes, hoppers, machine guards, conveyors, etc. Certain rules regarding the thickness of the damping material in relation to the thickness of the structure to be coated must be observed in order to obtain adequate noise reduction.

- Minimizing gaps in machine guards or covering them with acoustic absorbent material.

- Replacing chain and gear drives with belt drives.

- Replacing metal gears with plastic gears.

- Using gears with tooth patterns which provide a quiet run (e.g., chevron and other helical patterns).

- Replacing metal parts with plastic ones.

- Replacing motors with quieter ones.

What engineering controls can be used to reduce aerodynamic-induced noise?

Back to topNoise control specialists recommend the implementation of the following engineering controls to reduce the noise associated with unstable air or water flow.

- Minimize fluid velocity and increase the diameter of pipes.

- Minimize turbulence by using large, low-speed fans with curved blades. The following table illustrates the correlation between the reduction of the speed of the fan and the noise attenuation.

| Speed Reduction | Noise Reduction dB |

|---|---|

| 10% | 2 |

| 20% | 5 |

| 30% | 8 |

| 40% | 11 |

| 50% | 15 |

(From: WorkSafe Victoria (2023) - Controlling fan and ventilation noise)

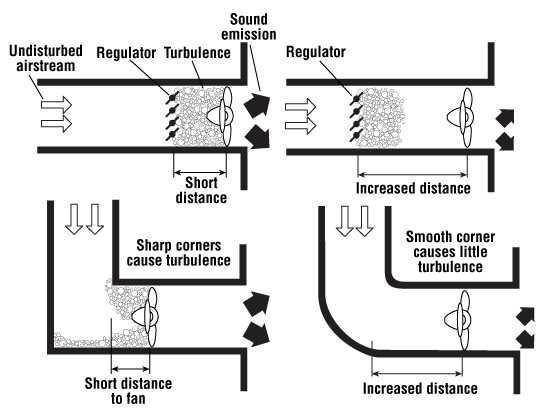

- Avoid elbows when installing a centrifugal fan.

- Increase the distance between fans and devices that may reduce efficiency and increase noise (such as bends, dampers, etc.).

Figure 1: How to avoid turbulence (Figure from: World Health Organization, (1996). “Engineering Noise Control”)

- Choose quiet, entraining nozzles (nozzles designed to draw and transport the air quietly) instead of simple nozzles.

What are other engineering controls?

Back to topEnclosure and isolation

Noisy equipment can be enclosed in spaces or rooms that have special acoustic features – such as sound isolating, acoustic louvres, or sealed windows and doors. The degree of sound attenuation will depend on the noise-reduction properties of the materials used to build the room.

In many cases, only the individual machine is enclosed. The enclosure can be total or partial. Partial enclosures are preferred where worker access for operation or maintenance is required. The noise attenuation offered by the partial enclosures is lower than that of a total enclosure. An alternative to an enclosure of the equipment is the enclosure of the workers. The workers may operate the equipment remotely from an isolated room.

Isolation is used to reduce the sound transmitted through vibrations. The equipment is isolated from radiating surfaces by materials such as springs, elastomeric materials, cork, and foam rubber. For example, heavy vibrating machinery can be supported by isolating springs and rubber inserts, or vibrating pipes can be supported by brackets that are padded by rubber isolators or by springs.

Acoustic barriers

Acoustic barriers are panels made of sound-absorbing material which are placed between the source of noise and the worker. Panels must be designed appropriately (e.g., panels placed in highly reflective rooms are not always effective in attenuating the noise that reaches the worker).

Installation of silencers in the ducts and at pneumatic exhausts

Silencers are devices that allow the fluid to pass but restrict the passing of the sound by reflecting or dissipating the sound. Sound dissipation occurs in silencers containing absorbing materials. In reflective silencers, the sound propagation is reduced due to the existence of expansion cambers (as in a car muffler) or openings.

What other general measures can I take to control the noise?

Back to topPerform regular maintenance. Focus on identifying and replacing worn or loose parts, lubricating moving parts, and ensuring that rotating equipment does not go off balance.

Substitute noisy processes with quieter ones. For example, replace:

- Pneumatic ejectors with mechanical ones

- Rolling or forging with pressing

- Impact riveting with welding

- Circular saw blades with damped blades

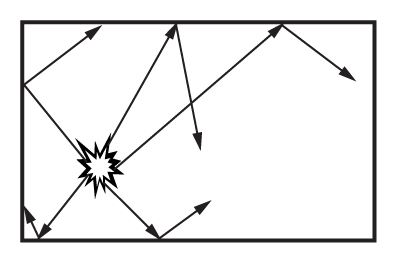

Reduce sound reverberation in the room. Reverberation happens when the sound produced in an enclosure hits a hard reflective surface. The sound reflects back in the room and adds to the original source. The strength of the reverberation decreases with the distance from the source to the reverberating surface. In some cases, the reverberated sound may dominate the original sound. In such cases, padding the reflective surfaces with sound-absorbing materials will reduce the sound level.

Figure 2: Sound reverberation in a room

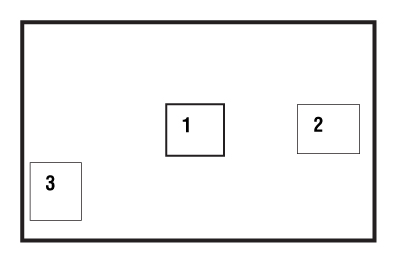

Reverberation can be reduced by arranging the equipment in the room in such a way that the equipment is not too close to too many reflective structures. The sound level of a noise source placed near hard reflective surfaces increases by 3 dB for each surface. For example, if a motor is placed directly on the floor, close to one of the walls of the room (the motor is close to two surfaces) (Figure 3, Position 2), the sound level will increase by 6 dB; if the same motor is placed in the corner of the room (close to three surfaces: two walls and the floor) (Figure 6, Position 3), the sound level will increase by 9 dB.

Figure 3: Sound reflection and placement of equipment in the room

Another way to reduce the sound radiation is to reduce the radiating surface (e.g. covering a transmission gear with a mesh enclosure instead of a solid box).

- Fact sheet first published: 2017-01-17

- Fact sheet last revised: 2024-03-20