Storage Safety Cabinets for Hazardous Chemicals

On this page

- What are storage safety cabinets, and what is their purpose?

- What are flammable liquid safety cabinets?

- Are storage safety cabinets regulated?

- Where can storage safety cabinets be placed in the workplace?

- How are storage safety cabinets selected?

- How do I know if a storage safety cabinet complies with a particular standard?

- Are there specific marking or labelling requirements for flammable liquid storage safety cabinets?

- When should storage safety cabinets be used in a workplace?

- Are there different sizes for storage safety cabinets, and is there a maximum capacity for them?

- Should storage safety cabinets be vented?

- Should storage safety cabinets be grounded?

- Are there storage safety cabinets for gas cylinders or containers, and what are the requirements?

- Which storage safety cabinet is appropriate for the hazardous chemicals at the workplace?

- Why are there so many different colours for hazardous material storage safety cabinets?

- Can a flammable liquid storage safety cabinet be modified?

- Are there limits on the number of cabinets that can be present?

- Can incompatible materials be stored in the same storage safety cabinet?

- How are containers stored in the safety cabinets?

What are storage safety cabinets, and what is their purpose?

Back to topStorage safety cabinets are cabinets used to store hazardous chemicals such as acids, bases, oxidizers, flammable, and other types of chemicals. Many storage safety cabinets are manufactured to store specific types of hazardous chemicals. Their purpose is:

- To provide temporary protection from a fire

- To separate incompatible materials to avoid unintentional mixing, which could result in damage to property or a fire

- Restrict access to products that might be harmful or dangerous to personnel who are not qualified to use or handle the product.

What are flammable liquid safety cabinets?

Back to topFlammable liquid storage safety cabinets are cabinets that are specifically designed for the storage of flammable liquids. These cabinets provide temporary protection from a fire. For the cabinet to be effective, it must be used according to local fire code requirements and the manufacturer’s instructions.

Are storage safety cabinets regulated?

Back to topStorage safety cabinets are often regulated under local fire codes.

Requirements may also be specified in the jurisdiction’s health and safety legislation and substance-specific regulations or standard. For example, British Columbia’s Occupational Health and Safety Regulations include mention of approved storage cabinets in Sections 5.33 to 5.35.

Most jurisdictions have either adopted the National Fire Code of Canada or the Code with some modifications. The exceptions are Ontario, which has its own Fire Code, and Prince Edward Island (PEI) has adopted the “National Fire Protection Association (NFPA) 1 Fire Code” and the “NFPA 101 Life Safety Code”.

National Fire Code of Canada (NFC)

- Adopted by New Brunswick, Newfoundland and Labrador, Nova Scotia, Manitoba, Saskatchewan, and Quebec’s major municipalities

- Adopted with some modification by Northwest Territories, Nunavut, and Yukon

Similar fire codes to the National Fire Code are Alberta, British Columbia, and Ontario.

National Fire Protection Association (NFPA) (USA) codes can be viewed for free after registration.

NOTE: Specifications for biological safety cabinets are not included in the fire codes. Requirements for such cabinets are generally required in the health and safety legislation for cytotoxic drugs or biologically hazardous materials.

This OSH Answers document does not focus on the storage of biologically hazardous substances.

Where can storage safety cabinets be placed in the workplace?

Back to topThey must be placed at a location that meets the local fire code requirements, such as Part 2 in the National Fire Code of Canada, and as instructed by the manufacturer. Storage safety cabinets can be placed under a counter, along a wall, or be wall-mounted or stacked.

Select a location that does not block exits, walkways, evacuation routes, etc. Generally, manufacturers recommend that storage safety cabinets be located in well-ventilated and low-humidity environments that comply with the local fire code.

Check with applicable insurance providers to determine if they have additional requirements.

How are storage safety cabinets selected?

Back to topStorage safety cabinets are generally selected based on the local fire code requirements, and manufacturer specifications. All types of cabinets (e.g., corrosive, oxidizers, toxic, flammable) must meet the required fire rating to protect the items stored. The fire-resisting material must be compatible with the hazardous chemicals in the containers in case of an unintentional spill.

Local fire codes will specify the standard that the storage safety cabinet must meet. The specification for cabinets may vary for different jurisdictions. The standards for storage safety cabinets in the different jurisdictions are as follows:

- All jurisdictions (except Prince Edward Island): ULC/ORD C1275 Standard for Safety for Flammable Liquid Storage Cabinets

- Ontario – in addition to ULC/ORD C1275 standard, Ontario also accepts the following standards:

- ULI 1275, “Flammable Liquid Storage Cabinets”,

- “FM APPROVED” by FM Global, and

- Those listed as meeting NFPA 30, “Flammable and Combustible Liquids Code.”

- Prince Edward Island (Check NFPA 1 in case there is a different standard for materials with a specific hazard (e.g., peroxides)):

- NFPA 1 Fire Code (2021) - Section 60.5.1.18 “Hazardous Materials Storage Cabinets” and Section 66.9.4 “Liquid Storage Cabinets,”

- NFPA 400 (2022) (cited in NFPA 1) – Section 21.2.17 “Gas Cabinets,”

- NFPA 30 Flammable and Combustible Liquids Code (cited in NFPA 1). NOTE: ULC1275and FM 6059 conforming storage safety cabinets are considered to be equivalent to the NFPA 30 specifications

Storage safety cabinets for substance-specific hazards such as biohazardous or pyrophoric materials will need to meet additional requirements or standards.

How do I know if a storage safety cabinet complies with a particular standard?

Back to topThe storage safety cabinet must have an approval label, which meets the requirements of the standard it was manufactured to. When selecting cabinets, make sure it is certified by the appropriate organization. It is also a good practice to verify the cabinet’s certification by contacting the appropriate certifying organization in case the cabinet is counterfeit. In addition, the manufacturer will have a technical or specification document for their cabinets which should be compared to the requirements in the applicable Code or legislation.

For example, a cabinet that is compliant with the ULC standard will have the following ULC certification mark:

Examples of Factory Mutual (FM) approval marks are below:

[Factory Mutual Approval Mark]

Safety storage cabinets that comply with NFPA (e.g., NFPA 30) will be marked with an “N” code.

Are there specific marking or labelling requirements for flammable liquid storage safety cabinets?

Back to topMarking and labelling requirements are required specifically for flammable liquid storage safety cabinets. The fire codes do not specify similar requirements for safety cabinets that are intended for other hazardous chemicals.

The National Fire Code of Canada requires that flammable liquid cabinets be labelled in conspicuous lettering to indicate that the cabinet contains flammable chemicals and that open flames must be kept away. Meanwhile, NFPA 1 and NFPA 30 require specific wording and font size, colour, as well location where they should be placed on the cabinet. See below for an example:

UL 1275 and FM:UL 1275 and FM:

“FLAMMABLES - KEEP FIRE AWAY”

NFPA 1 and NFPA 30:

“WARNING

FLAMMABLE

KEEP FIRE AWAY”

Storage safety cabinets for other hazardous chemicals must also be labelled according to health and safety legislation, WHMIS requirements, or safe industry practices. Labels should state the type of hazardous chemical stored in the safety cabinet. For example, WHMIS pictograms can be used. This labelling informs workers and emergency responders of the hazards of the stored items in the cabinet.

When should storage safety cabinets be used in a workplace?

Back to topGenerally, storage safety cabinets are used when:

- Segregation or separation distance of 6 metres (20 feet) or more cannot be accommodated for incompatible hazardous chemicals that need to be used daily.

- The amount of hazardous chemicals needed at a workplace is above the maximum allowed amount in the local fire code. Note that the maximum amount for a specific type of hazardous chemical varies:

- for different occupancies (e.g., mercantile, laboratory, chemical warehouse, incidental use, etc.), and

- on the classification of the hazardous chemical according to the applicable fire code.

If there is no specification for a maximum allowed quantity in the local fire code or health and safety legislation, then for due diligence reasons, good practices need to be followed. For example, “NFPA 430 for the Storage of Liquid and Solid Oxidizers” specifies the maximum allowed quantities for different types of oxidizing chemicals.

See the table below for examples of the maximum allowed quantity per fire compartment of Class IB flammable liquid that can be present ‘for use’ at different occupancies settings as stated in the National Fire Code of Canada. Note that some of the jurisdiction’s health and safety legislation or insurance companies may have lower maximum quantity requirements.

Table 1: Maximum amount of flammable liquid stored (from National Fire Code of Canada, 2020)

| Occupancy | The maximum amount of Class IB (*) flammable liquid such as acetone outside of a flammable storage cabinet or room in the absence of other flammable liquids |

| Business and Personal Services, Educational and Care, or Detention Occupancies | 5 L or less in a single room 10 L in a single fire compartment (**) with a fire-resistance rating of at least 45 minutes |

| Automotive shops or industrial arts areas of an education facility | 25 L or less |

| Assembly and Residential Occupancies | 30 L or less fire compartment with a fire-resistance rating of 1 hour |

| Mercantile Occupancies | Not more than 0.3 L/square meters (not sprinklered) in a single suite OR maximum of 300 L / single suite Not more than 1 L/square meter (sprinklered) in a single suite or a maximum of 1000 L / single suite |

| Incidental use | 5000 L |

(*) Flammable liquid classification – see Article 4.1.2.1 in the National Fire Code of Canada

- Class IA liquids have a flash point below 22.8°C and a boiling point below 37.8°C.

- Class IB liquids have a flash point below 22.8°C and a boiling point at or above 37.8°C

- Class IC liquids have a flash point at or above 22.8°C but below 37.8°C

- Class II liquids have a flash point at or above 37.8°C but below 60°C

- Class IIIA liquids are liquids that have a flash point at or above 60°C but below 93.3°C

(**) Fire compartment means an enclosed space in a building that is separated from all other parts of the building by enclosing construction providing a fire separation having a required fire-resistance rating.

Are there different sizes for storage safety cabinets, and is there a maximum capacity for them?

Back to topYes, manufacturers offer different sizes of cabinets. Generally, the capacity of storage safety cabinets ranges from 15 L to 500 L.

The National Fire Code of Canada, adopted by almost all jurisdictions (except PEI), sets the maximum amount of flammable and combustible liquid stored in a cabinet to be 500 L. However, Ontario’s Industrial Establishment Regulations limit the maximum to 235 L per cabinet. The maximum amount of flammable liquids for PEI is stated in the NFPA 1 Fire code, which is 120 gals (460 L) (same requirement as in NFPA 30 cited in NFPA 1).

The maximum amount of non-flammable hazardous chemicals in storage safety cabinets is not specified in the National Fire Code of Canada. Follow good practices such as those of NFPA to determine what the quantities should be for a specific occupancy.

Should storage safety cabinets be vented?

Back to topThe need for ventilation depends on the type of hazardous chemicals stored in the cabinet. Storage safety cabinets for flammable liquids that are not toxic are not recommended to be ventilated as it has been shown that it is not necessary for fire protection. However, a cabinet will need to be vented according to the requirements of the local fire code or to good practices when it is used to store:

- toxic or very toxic chemicals,

- chemicals that decompose and release flammable or toxic gases, or

- gas cylinders or containers.

Generally, storage safety cabinets include dual vents. Depending on the hazardous chemical, the fire codes require vents to be:

- Sealed with a material that offers the same fire protection level as the cabinet. Note that if the manufacturer supplied bungs (stoppers) with the cabinet, they should be used.

- Vented outdoors with vent pipes. The fire rating for the piping must be at least equivalent to that of the cabinet itself. Mechanical exhaust ventilation is preferred and should comply with good practices such as “NFPA 91 Standard for Exhaust Systems for Air Conveying of Vapors, Gases, Mists, and Particulate Solids “. In addition:

- the piping or ducting must be directed outdoors to a safe location or to a treatment device designed to control volatile organic compounds and ignitable vapours

- the cabinet should be vented from the bottom with makeup air supplied from the top

- manifolding of vents from multiple storage cabinets is not recommended

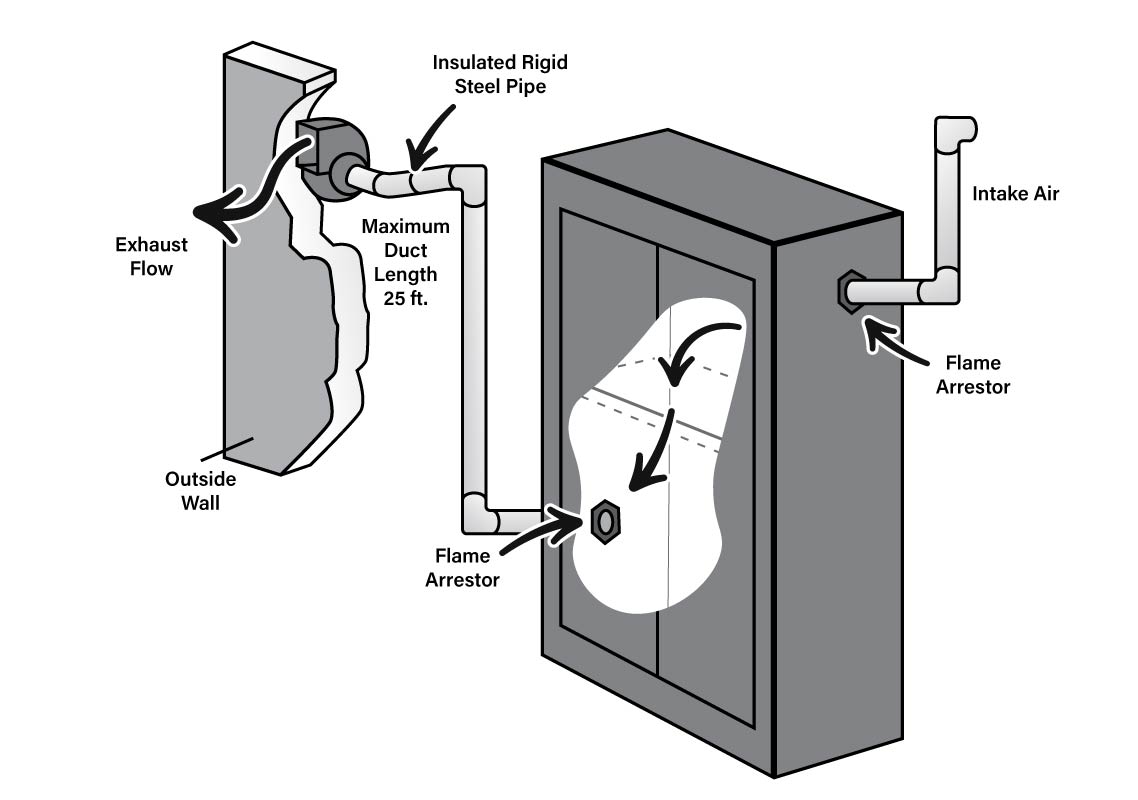

The following procedure should be followed when a cabinet must be vented:

- Remove both metal bungs and replace them with flash arrester screens (normally included with the cabinets). The top opening is used as a fresh air inlet.

- Connect the bottom opening to an exhaust fan using substantial metal tubing having an inside diameter no smaller than the vent. The tubing or piping should be rigid steel.

- The fan should have a non-sparking fan blade and shroud. It should exhaust directly to the outside.

- The total run of exhaust piping or ducting should not be more than 7.5 meters (25 feet)

See the illustration below for a sample method to vent a liquid storage cabinet used for toxic liquid chemicals.

Should storage safety cabinets be grounded?

Back to topA hazard and risk assessment needs to be done by a safety specialist to determine if the storage safety cabinets must be grounded. Generally speaking, if the cabinets are constructed of metal or other conductive material, they must be grounded when Class 1 flammable liquids are being dispensed in the cabinet.

If the cabinets are constructed of metal or other conductive material, they may need to be grounded as a precautionary measure when:

- The cabinet contains flammable liquid containers, but the flammable liquids are not being dispensed.

- The cabinet is located in an area where a flammable or ignitable atmosphere can exist, regardless of the type of chemical that is stored inside the cabinet. For example, a storage safety cabinet specific for corrosive chemicals may need to be grounded when the cabinet is located in an area where a flammable or ignitable atmosphere exists.

Notes:

- A manufacturer may include on the cabinet a built-in grounding lug for connection with an antistatic wire to safely ground the cabinet to earth ground. An optional seismic bracket may also be included to secure the cabinet to the floor or wall for an extra measure of security when increased stability is needed.

- Storage safety cabinets made of non-conductive construction materials without anti-static features cannot be grounded. Cabinets made of non-conductive construction materials should not be used for storing flammable liquids or placed where an ignitable atmosphere exists.

Are there storage safety cabinets for gas cylinders or containers, and what are the requirements?

Back to topYes. When the maximum allowed quantity outside a storage room is exceeded, gas cylinders can be stored in a gas safety cabinet. Note that this quantity varies for different occupancies and the hazard classification for the gas. For example, when gas cylinders contain a flammable gas that is lighter than air, according to the National Fire Code of Canada, the total quantity must not be more than:

- 60 cubic meters in a building of combustible construction that is not sprinklered.

- 170 cubic meters in a sprinklered building or a building of non-combustible construction.

The National Fire Code of Canada does not have specifications for other gasses. However, the National Fire Code instructs users to follow good practices such as the NFPA 55, “Compressed Gases and Cryogenic Fluids Code,” when it does not have requirements for specific situations. This standard is also cited in NFPA 1 for the storage of gases. The gas cabinet specifications are provided in Section 6.18 of the NFPA 55. Section 6.18 requires the gas cabinets to be ventilated and recommends that incompatible gases be stored in separate cabinets. The following maximum quantities for gas cabinets are recommended:

- Must not contain more than three cylinders, containers or tanks where each has greater than or equal to 0.28 cubic meters. or

- Must not contain more than 30 cylinders where the capacity of each is less than 0.28 cubic meters

Which storage safety cabinet is appropriate for the hazardous chemicals at the workplace?

Back to topTo know which cabinet must be used, you need to:

- Prepare a list of the hazardous chemicals that are being used at the workplace

- Determine the type of hazards (e.g., flammable, corrosive, etc.) each chemical presents. You can use the Workplace Hazardous Information System (WHMIS) or the Transportation of Dangerous Goods (TDG) classification. Generally, both classifications are provided in the safety data sheet.

- Check the local fire code requirements for the safety cabinet.

Determine the type of storage safety cabinets needed by making sure the manufacturer’s technical data sheet or specifications match the chemical’s hazard(s) and local fire code requirements. Manufacturer information is generally available on their website.

For example, the safety data sheet for substance A reports that it is classified as follows WHMIS Hazard class: Corrosive to Metals — Category 1 and TDG Class 8 Corrosive. Based on substance A’s corrosivity hazards, a “polyethylene corrosive and acid” cabinet should be selected.

Why are there so many different colours for hazardous material storage safety cabinets?

Back to topColour-coded cabinets are not required or specified in the National Fire Code of Canada, standards for storage safety cabinets, nor in health and safety legislation. Manufacturers produce storage safety cabinets in different colours for the following reasons:

- Improves the safety of emergency responders (e.g., firefighters) so they can quickly identify the hazards of the chemicals in the cabinet

- Reduces the potential of storing incompatible chemicals together. By identifying the intended use of the safety cabinet, the risk of storing incompatible chemicals together is significantly reduced

- Allows workers to quickly identify the type of hazardous chemicals in the cabinet

- Allows for easy organization of chemicals, fuels, pesticides, and segregation of incompatible hazardous items

Most companies follow good practices and use specific colours for liquids that are a specific hazard. These colours are:

- Yellow: Flammable chemicals and liquids

- Red: Paints, inks, and other combustible liquids

- Blue: Corrosive and hazardous liquids and solids

- Green: Pesticides and insecticides

- Silver or Neutral: Laboratory cabinets

- White, Beige, or Gray: Waste or outdoor lockers

Can a flammable liquid storage safety cabinet be modified?

Back to topSince the storage safety cabinet is tested in its original manufactured form with the original construction material per a standard stated in the fire code, any modifications will generally affect the cabinet's performance. When cabinets are modified, the certifying agency may require additional tests, inspections, examinations, or other evaluations that will demonstrate that the modified cabinet product continues to fulfill requirements. Unless the modifications have been determined to be insignificant to the structural integrity and fire performance of the cabinet, any other modification will generally void the approval of that product and the manufacturer’s warranty.

Are there limits on the number of cabinets that can be present?

Back to topYes. The maximum number of cabinets that can be present will vary for different occupancies and hazard classifications of the chemicals. For example:

Table 2: Number of Storage Safety Cabinets (from the National Fire Code of Canada)

| Occupancy | Number of cabinets allowed for storage of flammable liquids per fire compartment |

| Business and Personal Services, Educational and Care or Detention Occupancies | One cabinet |

| Assembly and residential Occupancies | One cabinet |

| Mercantile Occupancies | Not specified |

| Care, treatment, or detention occupancies | One cabinet |

| Industrial occupancy | Three cabinets and the distance between groups of three cabinets must be at least 30 metres |

Can incompatible materials be stored in the same storage safety cabinet?

Back to topIncompatible materials, regardless of their physical form (e.g., gas, liquid, solid), must never be stored in the same cabinet, unless storage cabinets are designed with non-combustible or half-an-hour vertical fire barriers or partitions or as required by the fire code. For example:

- Only compatible flammable liquids can be stored in the same flammable liquid storage safety cabinet. Flammable acids or reactive flammable chemicals cannot be stored with flammable solvents that will react with them. Although a flammable acid or flammable reactive chemical and a flammable solvent pose a similar hazard, they cannot be stored together in the cabinet because of their additional reactivity hazard.

- Corrosive chemicals such as acid and caustics cannot be stored together in a safety cabinet for corrosive substances. Acids and caustics can react rapidly and with the evolution of heat.

- Hazardous chemicals in glass containers must be stored in cabinets that provide extra protection for glass containers. This extra protection is needed because the glass will melt when it is exposed to fire. The melting point for glass is well above the standard requirement for the storage safety cabinet to limit the internal temperature at the center of the cabinet to about 163°C (325°F) upon exposure to a 10-minute fire test.

- Do not store gas cylinders or aerosols containing hazardous chemicals in safety cabinets that are designed for liquid storage only. Some health and safety legislations may allow for small aerosol containers to be stored together with liquids. Check the jurisdiction’s health and safety legislation.

- Toxic chemicals must not be stored together if they are not compatible.

- Toxic chemicals must not be stored together with products used for the preparation of cosmetics, pharmaceuticals, and foods.

Before putting materials of similar hazard in a cabinet, always check:

- the compatibility table 3.2.7.6 in the National Fire Code of Canada

- the safety data sheet for incompatible materials

- in absence of sufficient information in the safety data sheet, consult with the manufacturer

How are containers stored in the safety cabinets?

Back to top- Follow the manufacturer’s instructions

- Use shelf dividers and clear labelling organization

- Incompatible materials are not permitted in the cabinet

- Open containers such as open-topped cans or buckets are not permitted in the cabinet

- Always store hazardous chemicals in closed metal containers, safety cans, or plastic containers with anti-static components that prevent static build-up on metal containers or safety cans. Place all containers in secondary containment (e.g., small bottles can be placed in a tray) in case a container fails

- Remove the original cardboard packaging before the containers are placed inside the cabinet

- Do not store empty cardboard boxes or paper in the cabinet as it increases the risk of fire

- Do not overload shelves. Check capacity in the manufacturer’s manual

NOTE: Avoid storing items on top of or near the cabinet including used or oily rags, wastepaper, or other flammable materials.

- Fact sheet first published: 2023-02-15

- Fact sheet last revised: 2023-02-15